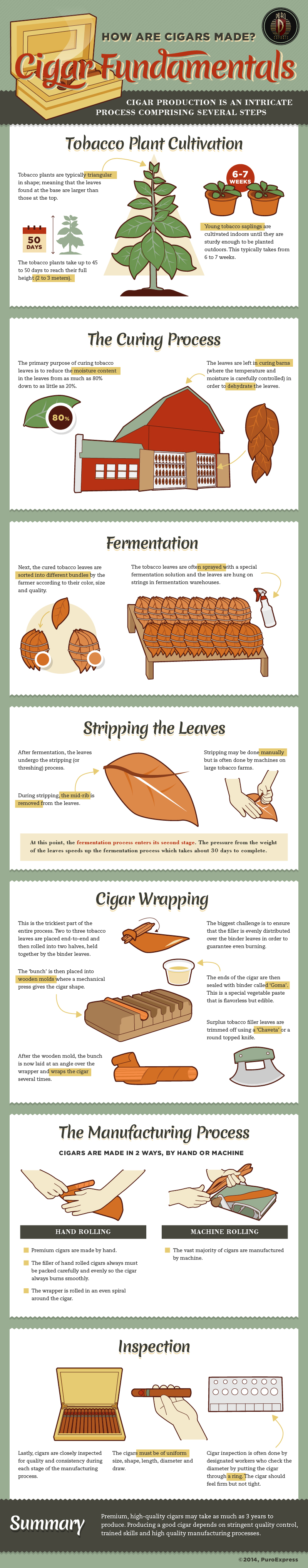

Cigar Fundamentals – An Infographic

Even though cigars have an old-school vibe, their customers vary across generation groups, including young adults.

Different from cigarettes, a cigar refers to a tobacco roll wrapped in tobacco leaves or other substances containing tobacco.

Before coming out to the market, cigars undergo a long production process, from plant cultivation to inspection.

There are at least seven steps to make cigars, which follow the sequence below.

Tobacco Plant Cultivation

Farmers cultivate young tobacco saplings indoors until they are sturdy enough, which needs six to seven weeks.

After they become sturdy plants, farmers move them and do the cultivation outdoors.

Tobacco plants take up to 45 to 50 days to reach their full height, as tall as two to three meters.

The Curing Process

The following process is curing. The curing process will take out 80% of the leaf moisture.

Farmers store the tobacco leaves in curing barns with controlled temperature and moisture to keep them dehydrated.

Fermentation

The following process is fermentation. But, before that, farmers sort the leaves into different bundles according to their colors, sizes, and quality.

Then, farmers spray them with a particular fermentation solution and hang the leaves on strings in the fermentation warehouse.

Stripping the Leaves

When the fermentation process is complete, tobacco leaves undergo the stripping process.

Farmers manually remove the mid-rib from the leaves or with a machine before using them as wrappers.

Cigar Wrapping

Wrapping cigars is the trickiest part of the whole process. Two to three tobacco leaves are placed end-to-end and then rolled into two halves, held together by the binder leaves.

The following process is placing the ‘bunch’ into wooden molds where a mechanical press gives the cigar shape. After that, farmers wrap them again several times.

Farmers seal the ends of the cigar with edible flavorless vegetable paste and trim the surplus tobacco filler leaves with a round-topped knife.

The Manufacturing Process

Workers can do the manufacturing process in two ways, manually and with machines.

Usually, premium cigars are handmade to ensure filler quality, where workers roll the wrapper in an even spiral around the cigar.

However, as technology has gotten better, the vast majority of cigars are manufactured by machines.

Inspection

When the manufacturing process is complete, cigars undergo an inspection to check their quality and consistency.

They must be identical in size, shape, length, diameter, and draw. Inspectors commonly use a tool with holes to check cigars’ diameter.

Closing

The making of cigars needs a long process. Usually, the entire process takes three years to finish.

Moreover, producing premium and high-quality cigars requires stringent quality control, trained skills, and high-quality manufacturing processes.

To learn more about cigars production, let’s take a look at the infographic below.